marble calcium grinding

2023-03-16T14:03:06+00:00

Calcium Carbonate Grinding Union Process

Calcium Carbonate Grinding Calcium carbonate exists in the earth’s crust in such natural forms as chalk, limestone and marble Undeniably one of the most prevalent compounds Dec 20, 2021 Dry processing requires a series of reduction procedures involving grinding and otherwise physically reducing material into smaller and smaller particles Calcium Carbonate Manufacturing Process and Jan 28, 2022 These cleaners soften and degrade marble; during grinding, you will lose more stone than you intended Repair Any Cracks Before you sand or grind a marble surface, fill in any small cracks,Can You Sand or Grind Marble Down? Home Guides

Daswell Ground Calcium Carbonate Process CaCO₃ Plant

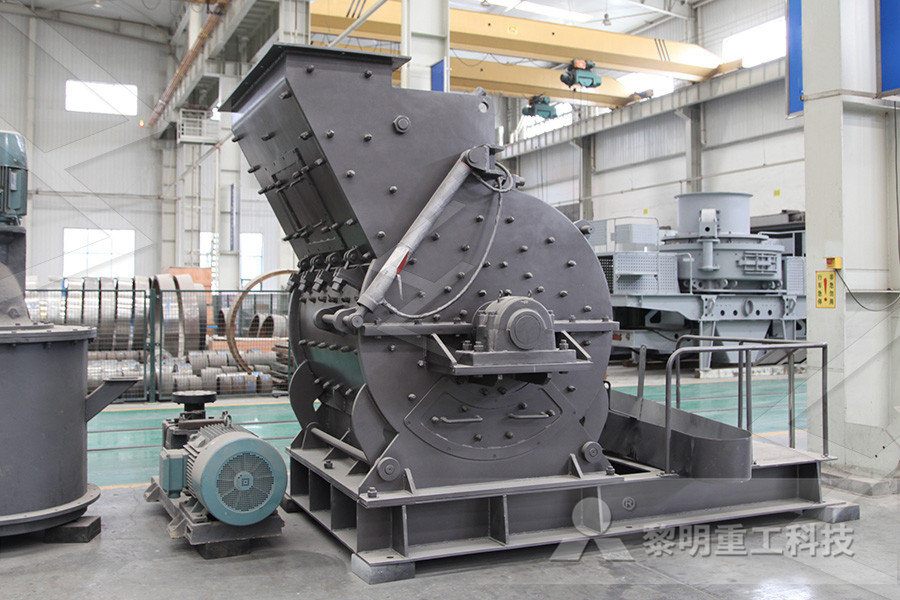

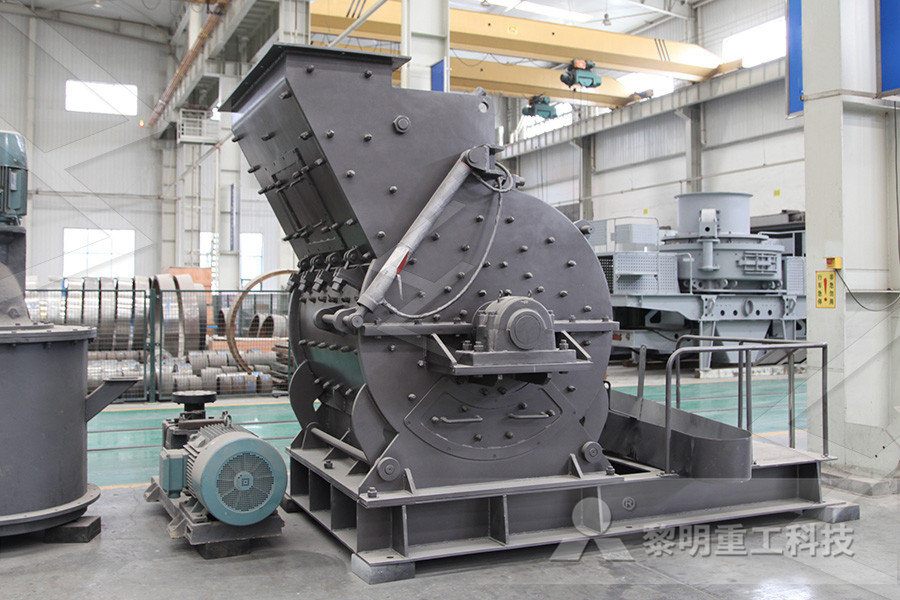

The whole ground calcium carbonate production process consist of crushing, grinding and coating After the raw material is quarried, the limestone or marble is crushed to smaller Limestone constitutes approximately 10 percent of the sedimentary rocks exposed on the earth’s surface Either limestone or marble may be used as the basis for crushed or ground calcium carbonate Ground calcium Ground Calcium Carbonate (GCC) Minerals Marble pendulum grinding mill can process marble into fine powder for a wide range of applications Marble powder is a heavy calcium powder that mainly composed of Tips on Choosing the Right Marble Pendulum Grinding Mill

How to Choose a Suitable Calcium Carbonate Grinding Mill

Jul 2, 2019 For commercial manufacturing, dry grinding of calcium carbonate involves crushing and grinding basic materials such as limestone or marble And there are Calcium Carbonate Products MARBLE HILL, GA Marble Hill, GA G High Brightness, High Purity Marble G Hegman Grind (ASTM D1210) Typical Physical Properties — Ultra Hubercarb G Series Calcium Carbonate ProductsCalcium powder is mainly white powder formed by grinding limestone, calcite, marble and other ore powder, commonly known as heavy calcium What equipment can be used to What are some recommendations for high calcium stone

Calcium Carbonate Manufacturing Process and Equipment

Dec 20, 2021 Dry processing requires a series of reduction procedures involving grinding and otherwise physically reducing material into smaller and smaller particles Screened grade material usually falls within 640 mesh (4003360 microns) on average When using marble for calcium carbonate manufacturing, processing results in an even purer Precipitated Calcium Carbonate PCC stands for Precipitated Calcium Carbonate—also known as purified, refined or synthetic calcium carbonate It has the same chemical formula as other types of calcium carbonate, Precipitated Calcium Carbonate Minerals Product Description StonePro 5X Polishing Powder is a high quality traditional polishing powder for polishing marble, travertine, limestone and all calcium based natural stone surfaces Can be used on floors, 5x Polishing Powder Marble, Travertine, Limestone

Worker Exposure to Silica during Countertop

Calciumbased stones, including limestone and certain varieties of marble (eg, calcite, dolomite, and onyx), contain little or no silica In contrast, granite can contain up to 45 • Use grinding and drilling tools equipped with dust shrouds coupled with LEV and a Jul 2, 2019 For commercial manufacturing, dry grinding of calcium carbonate involves crushing and grinding basic materials such as limestone or marble And there are several kinds of calcium carbonate grinding mill for dry grinding, such as ball mill, Raymond mill, vibrating mill, roller mill, vertical mill, jet mill, and so onHow to Choose a Suitable Calcium Carbonate Grinding MillCalcium Carbonate Products MARBLE HILL, GA Marble Hill, GA G High Brightness, High Purity Marble G Hegman Grind (ASTM D1210) Typical Physical Properties — UltraFine and Fine Products G2 2 95 19 02 69 39 55 0005 65 G2T Treated 2 95 17 02 39 55 0005 65 G3 32 95 18 02 57 47 60 0005 6 G3THubercarb G Series Calcium Carbonate Products

How to Choose a Calcium Carbonate Grinding Mill DASWELL

Aug 13, 2022 In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, storage bins, grinding mill, dust collectors, classifiers and other equipmentCultured marble is artificial marble, a composite made of dust from marble or calcium carbonate mixed with polyester resins or acrylics and then poured onto a flat molding surface or into fixture molds Usually, a clear coat grinding does not need to extend into the color unless the colored surface needs to be exposed to remove any burn Cultured Marble Repair Procedures MultiTech ProductsCalcium powder is mainly white powder formed by grinding limestone, calcite, marble and other ore powder, commonly known as heavy calcium What equipment can be used to produce heavy calcium? This is a common question that many customers are asking us We are recommend a variety of heavy calcium grinding equipmentWhat are some recommendations for high calcium stone grinding

How To Make Calcium Carbonate From Marble?Industry Newsgrinding

Calcium carbonate can be made from marble by first crushing the marble to a fine powder and then reacting it with an acid, such as hydrochloric acid, to produce carbon dioxide and calcium chloride The reaction can be written as: CaCO3 (marble) + 2 HCl (acid) > CaCl2 (calcium chloride) + CO2 (carbon dioxide) + H2O (water)CamelCal is a premium, ultrafine particle size, beneficiated, wet ground marble Its primary use is in compounded plastics to increase impact strength and stiffness Productivity gains may also be realized due to increased thermal conductivity CamelCal can also be used in coatings where gloss is importantCalcium Carbonate Wolf Container Chemical CompanyGround Calcium Carbonate(GCC) is usually made by grinding natural carbonate minerals such as calcite, marble and limestone It can be got by wet or dry process Currently, dry process is popular at home 1 Crushing Stage: Big blocks of natural carbonate minerals like calcite, marble or limestone would be crushed into particles within 15mm50mm Ground Calcium Carbonate(GCC) Grinding Mill mills

Removing Calcium Deposits From Stone

Jul 21, 2016 Removing calcium deposits from limestone, marble and travertine For all stone surfaces such as countertops and showers, we recommend cleaning daily Calcium carbonate exists in the earth’s crust in such natural forms as chalk, limestone and marble Undeniably one of the most prevalent compounds on earth, calcium carbonate has proven valuable in a variety of industries The paper, plastics, paints and coatings industries all rely heavily upon this chalky mineral, due in large part to itsCalcium Carbonate Grinding Union ProcessDec 20, 2021 When using marble for calcium carbonate manufacturing, processing results in an even purer mineral form However, limestone is generally used due to its lower cost The resulting ground calcium carbonate is then graded according to its specific properties, used for various uses, or processed further via wet processingCalcium Carbonate Manufacturing Process and Equipment

Getting Rid Of Those Pesky Calcium

May 20, 2013 When you have heavy calcium buildups on granite or slate, you can use a diluted solution Mineral Deposit Remover (MDR) and try to remove these white SAFECARB ground marble bridging agent is a highpurity, acidsoluble calcium carbonate used as a bridging and weighting agent in drilling, drillin, workover, and completion fluids Compared with limestone, the agent features higher hardness and purity, providing better acid solubility This calcium carbonate bridging and weighting agent can SAFECARB Ground Marble Bridging Agent SLB SchlumbergerCalcium Carbonate Products MARBLE HILL, GA Marble Hill, GA G High Brightness, High Purity Marble G Hegman Grind (ASTM D1210) Typical Physical Properties — UltraFine and Fine Products G2 2 95 19 02 69 39 55 0005 65 G2T Treated 2 95 17 02 39 55 0005 65 G3 32 95 18 02 57 47 60 0005 6 G3THubercarb G Series Calcium Carbonate Products

How to Choose a Suitable Calcium Carbonate Grinding Mill

Jul 2, 2019 For commercial manufacturing, dry grinding of calcium carbonate involves crushing and grinding basic materials such as limestone or marble And there are several kinds of calcium carbonate grinding mill for dry grinding, such as ball mill, Raymond mill, vibrating mill, roller mill, vertical mill, jet mill, and so onReconnaissance investigation of highcalcium marble in the Beaver Creek area, St Lawrence County, New York (Geological Survey circular; 774) Bibliography: p 1 Marble New York (State) St Lawrence Co high whiteness and ease of grinding to a fine, soft powder gion Marble for limeburning, crushed stone, and furnace flux was produced in Reconnaissance Investigation of HighCalcium Marble in Calcium powder is mainly white powder formed by grinding limestone, calcite, marble and other ore powder, commonly known as heavy calcium What equipment can be used to produce heavy calcium? This is a common question that many customers are asking us We are recommend a variety of heavy calcium grinding equipmentWhat are some recommendations for high calcium stone grinding

How To Make Calcium Carbonate From Marble?Industry Newsgrinding

Calcium carbonate can be made from marble by first crushing the marble to a fine powder and then reacting it with an acid, such as hydrochloric acid, to produce carbon dioxide and calcium chloride The reaction can be written as: CaCO3 (marble) + 2 HCl (acid) > CaCl2 (calcium chloride) + CO2 (carbon dioxide) + H2O (water)Cultured marble is artificial marble, a composite made of dust from marble or calcium carbonate mixed with polyester resins or acrylics and then poured onto a flat molding surface or into fixture molds Usually, a clear coat grinding does not need to extend into the color unless the colored surface needs to be exposed to remove any burn Cultured Marble Repair Procedures MultiTech ProductsAug 13, 2022 In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, storage bins, grinding mill, dust collectors, classifiers and other equipmentHow to Choose a Calcium Carbonate Grinding Mill DASWELL

Marble Grinding Mill Marble Powder Making Machine

Marble and calcite are all normal nonmetallic materials, can be process into different fineness of powder which called as heavy calcium carbonate after grinded by grinding mill or other mine equipment, can be widely used in papermaking, plastic, rubber, household chemicals, cosmetics, building materials, paints, pharmaceuticals, food and other industriesGround Calcium Carbonate(GCC) is usually made by grinding natural carbonate minerals such as calcite, marble and limestone It can be got by wet or dry process Currently, dry process is popular at home 1 Crushing Stage: Big blocks of natural carbonate minerals like calcite, marble or limestone would be crushed into particles within 15mm50mm Ground Calcium Carbonate(GCC) Grinding Mill mills